Industrial scale production combined with one-off custom projects.

A custom process for your projects!

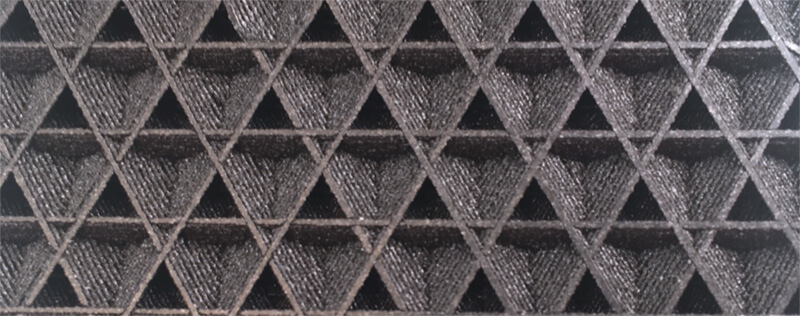

3D Post processing is a part of the 3D manufacturing cycle. To understand why 3D post-processing is needed, we need to know how 3D printing works and what happens to the printed parts once the production stage is over. We’ll show you some simple 3D post-processing procedures that can be applied to give your 3D printed parts a better finish and add more protection.